5 Mistakes to Avoid When Specifying Microcement

Microcement is one of the most versatile finishes in contemporary design. It’s being specified in projects all over Australian because of its seamless aesthetic, tactile finish, and adaptability (to name just a few reasons). From polished concrete–inspired floors to softly contoured bathrooms and bespoke joinery, it delivers that textural and high-end feel that you see in all your favourite design magazines.

However, beneath its sleek surface lies a material that requires precision, knowledge, and advanced science to perform well. While microcement is incredibly durable when correctly installed, it’s also unforgiving of shortcuts.

Below, we’ll explore the five most common mistakes made when specifying microcement, and how to avoid them.

1. Ignoring Substrate Preparation

The single biggest cause of microcement failure stems from poor substrate preparation. Because microcement is typically applied in layers only 2–3 mm thick, it mirrors every imperfection beneath it, from hairline cracks to uneven joints.

The substrate must be levelled (microcement is not supposed to be used as a self levelling compound) and any fractures bridged or reinforced. Extensive damaged should be fully repaired prior to microcement application.

A flawless finish requires an equally flawless base.

Must do’s:

Assess the substrate early. It must be clean, level, dry, and free of movement. Plywood, chipboard, or flexible subfloors must be reinforced or replaced. An old house experiencing significant foundation shifting might not be the best candidate for microcement, at least not without addressing the underlying structural issues first.

Plan for compatibility. Different substrates require different preparation, so always confirm that the surface aligns with the microcement manufacturer’s system.

Respect curing times. Don’t rush installing microcement over freshly poured screeds or new plaster — residual moisture can cause blistering or delamination later.

Think of microcement as a “finish coat,” not a fixer. It will not compensate for structural or surface defects; it will highlight them.

2. Overlooking Environmental Conditions

Microcement is sensitive to its installation environment. Both the application and curing stages are influenced by ambient temperature, humidity, and ventilation. Applying microcement in unsuitable conditions can lead to uneven curing, surface cracking or bubbling, poor adhesion or inconsistent sheen.

How to avoid this mistake:

Maintain ambient temperatures during application and curing according to product guidelines

Ensure relative humidity is stable

Prevent trades or heavy equipment from entering until the system has fully cured and been sealed

3. Incorrect Sealing

The sealer is often the unsung hero of a microcement system. It determines how your finish looks, feels, and performs. Poor sealing (or worse — no sealing) can compromise durability, stain resistance, and maintenance no matter how advanced the base formula is.

It’s also important that you match the sealer to the intended use e.g. ensure it holds up to foot traffic, moisture exposure, and your cleaning regime.

Understand that sheen levels (matte, satin, gloss) can also subtly change colour perception. Always approve final samples with the sealer applied.

At the end of the day, no sealer is bulletproof. There are some spills — like exposure to boiling oil or fake tanner — that require cleaning immediately to ensure sealers aren’t penetrated.

4. Treating All Microcements as the Same

It’s easy to assume that all microcements are equal, but that couldn’t be further from the truth. While we’ve been in the game since 1999 with Australia’s original microcement, there are now many other products on the market — and different manufacturers use different binders, aggregates, and other system components, each resulting in distinct performance.

For example, our X-Bond Microcement formula combines the hardy strength of stone with polymer modification, which provides the flexibility needed to resist cracking compared to more rigid formulas. This also ensures superior adhesion to the substrate for guaranteed resistance to de-lamination.

Ultimately, choosing a reputable microcement supplier who can provide technical guidance and certified applicators is key. A product backed by 25+ years of experience will set you up for success, and is worth more than a cheaper alternative with unknown performance.

5. Underestimating the Importance of Skilled Installation

Microcement application is a blend of art and science. Every layer is applied by hand, so even a great product can look poor if handled by an inexperienced installer.

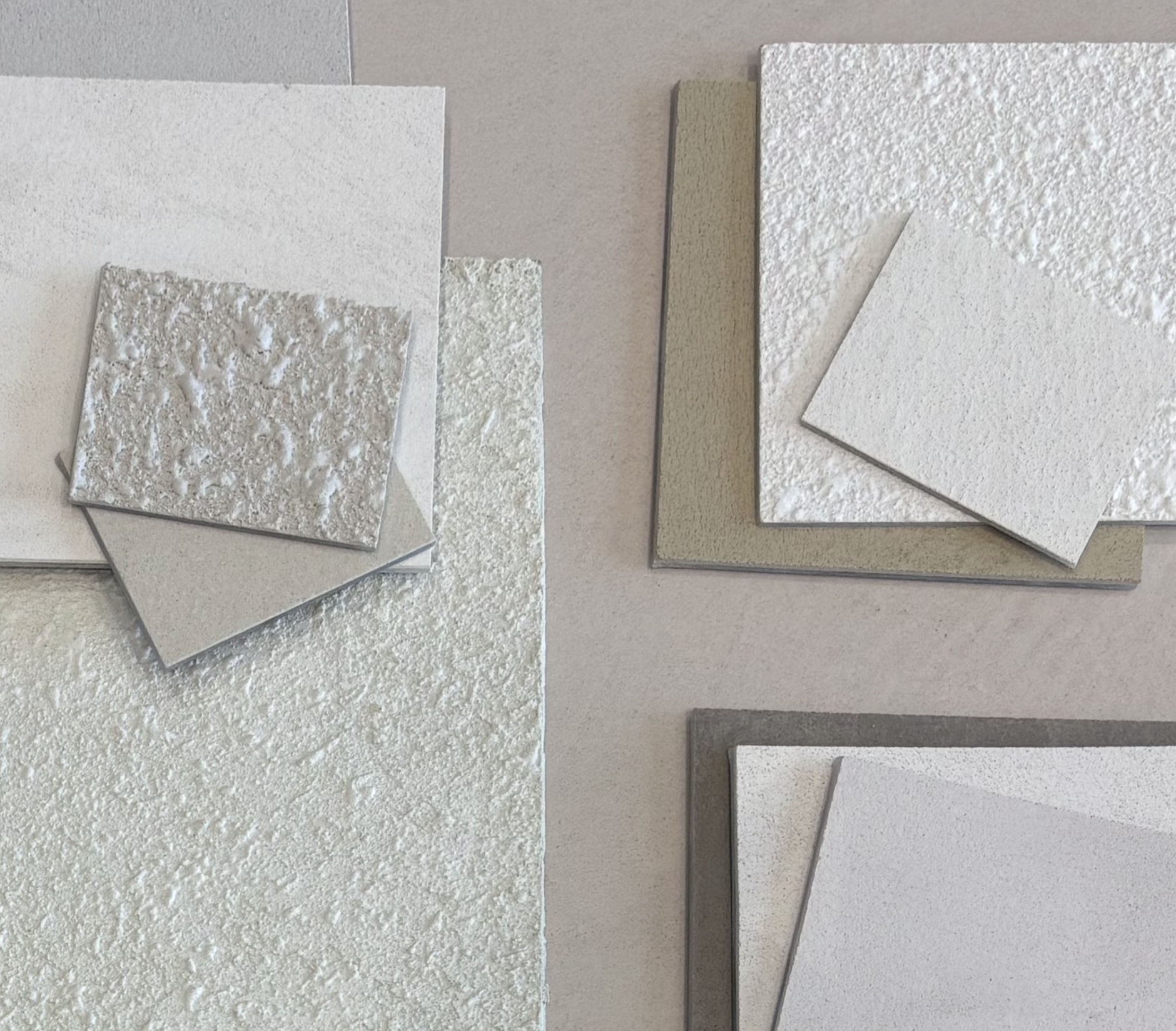

Before an applicator can even begin installing the microcement, every project will need at least a basic level of substrate prep and/or waterproofing — with some requiring extensive preparation work. Then, once the substrate is prepared, most microcement formulas need to be mixed with precise ratios of aggregates and colour pigments. From here, familiarity with a trowel; especially since the trowel marks are visible in the finial finish. The technique used will directly impact the texture and appearance of the surface. In our range, there are four texture finishes achieved using either a trowel, blade, and/or spray gun.

Therefore, while some brands are marketed as DIY-friendly, we only supply X-Bond to professionals who’ve completed our training course to ensure the best possible results.

It’s best to:

Work with certified or specialist applicators familiar with your chosen brand

Insist on a sample before committing to large areas

Include clear performance and aesthetic specifications in your project documentation — this sets expectations for consistency and quality

Microcement installation is a bespoke, handcrafted process. It requires skill, patience, and artistry. Invest in the right people and allow adequate time for the process.

When correctly specified and applied, microcement offers a finish that’s timeless, tactile, and endlessly adaptable. It bridges the gap between functionality and artistry, delivering a surface that’s both practical and beautiful.

To ensure a result that looks stunning and stands the test of time, avoid these five common mistakes: poor substrate preparation, ignoring environmental conditions, choosing the wrong sealer, treating all systems alike, and neglecting skilled installation.

Whether it’s a sculptural bathroom, a minimalist kitchen, or a commercial space that needs to balance elegance with durability, microcement rewards those who respect its craft.